Quality Is Our Culture

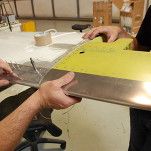

Techniform’s quality, technical and manufacturing leadership is committed to continual improvement of our processes and quality-management systems.

Techniform's system handles the most critical and stringent industrial quality requirements in today's manufacturing environment. Our key focus on continual improvement and value-added activities is achieved through:

- Lean Manufacturing & Six Sigma Principles

- Continuous Training for All Employees

- Acquisitioning State-of-the-Art Inspection Equipment

Techniform values the importance of In-process inspections as Quality requirements are increased and the Customer demands cost reductions. Implementation of these in-process inspections at critical points throughout manufacturing, minimizes the risk of defects. Techniform is focused on the needs of our customers and exceeding expectations.

The drive for higher quality

In the day and age when everyone is trying to cut corners, Techniform remains dedicated to unbeatable quality.

Techniform strives to constantly deliver top-quality products you can rely on for years to come.

We live and work by our qualty policy. "I am responsible for the quality of my work, through continual improvement of our processes, we will consistantly impress our customers".

SupplierDocuments / CQRS